Brisbane Plastic Injection Moulding Services

What is Plastic Injection Moulding?

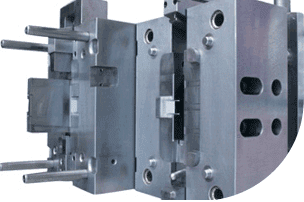

Once the design of a part is finalised a mould or tool is then built usually out of steel by a toolmaker.

This mould is then used in the process of injection moulding which involves heating up plastic granules to a molten state and injecting this material into the cavity of the steel mould.

What is the Cost of Injection Moulding?

In order for injection moulding to be cost effective the moulded parts must be produced in high volume.

For instance, moulding of 100 parts could cost $200 per part with the cost of the mould taken into consideration. On the other hand, moulding the same part in the quantity of 100,000 could translate to $1.20 per part. Therefore the higher the volume, the more cost effective injection moulding is.

What is the Cost of Injection Mould Tooling?

Having tools built can be a costly exercise due to the specialist equipment involved and the price is dependent on the following:

- the size of the mould

- the number of cavities in the mould

- the material the mould is made from as there are various grades of steel available on the finish on the moulded part

- the complexity of the design

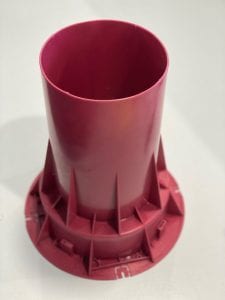

What is the Cost of Injection Moulded Parts?

The cost of moulded parts is dependent on several factors such as:

- part weight

- the material of the part is to be made from

- part thickness

- accuracy of the part

- the number of cavities of the same part in the mould

- the size and thickness of the part

- the quantity of your order

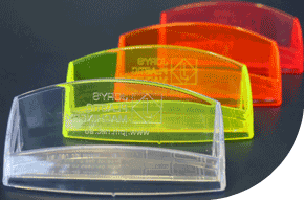

What Plastics Do We Use In Injection Moulded Parts?

Plastic materials we specialise in include:

- Polypropylene

- HDPE (High Density Polyethylene)

- LDPE (Low Density Polyethylene)

- HIPS (High Impact Polystyrene)

- Acetal

- Nylon

- ABS / ASA

- Thermoplastic Polyether Polyurethane Elastomer

Masterbatch

Masterbatch is a mixture of pigments encapsulated in a resin granule which enables the operator to colour or modify the characteristics of raw polymer economically during the plastics manufacturing process.

Enhanced masterbatches mean significant cycle time reductions which can be incorporated upon request.

Other options include high performance UV block for products that require UV protection.

How Can We Help?

How can JPM help you?

About Us

We are a family owned business based in Geebung.

We specialise in custom plastic injection moulding with over 30 years of experience.

Contact Us

Phone: 07 3630 8080

Address:

41 Kingtel Place

Geebung QLD 4034

Australia